All Product

Showing 1–12 of 174 results

-

Preorder 7-14 day Sakai Takayuki 33-Layer Damascus VG10 Knife Set

CHF649Our stock in Switzerland has sold out, and we are shipping new items from Japan to Switzerland. They will arrive in about a week.

-

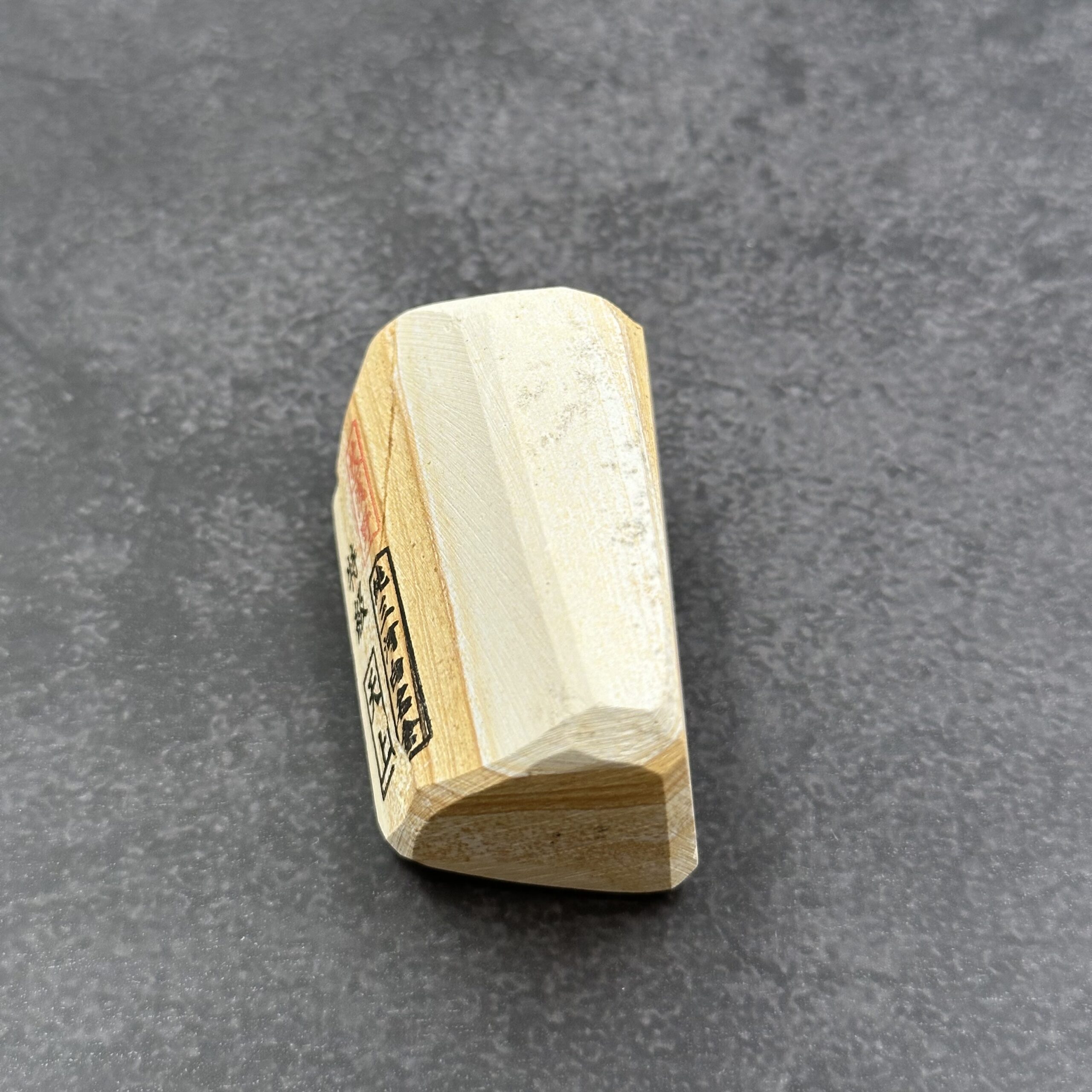

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 66g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

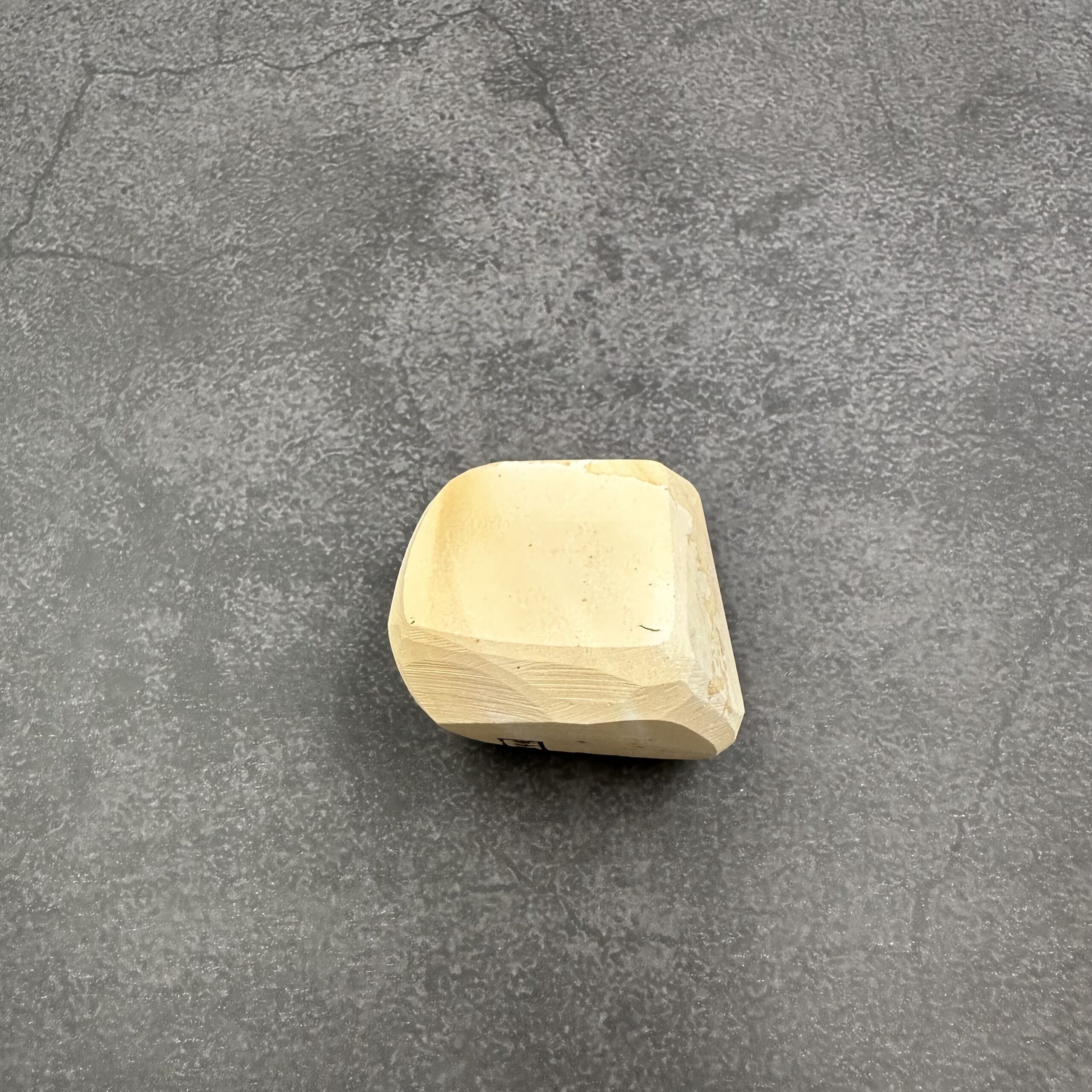

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 58g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

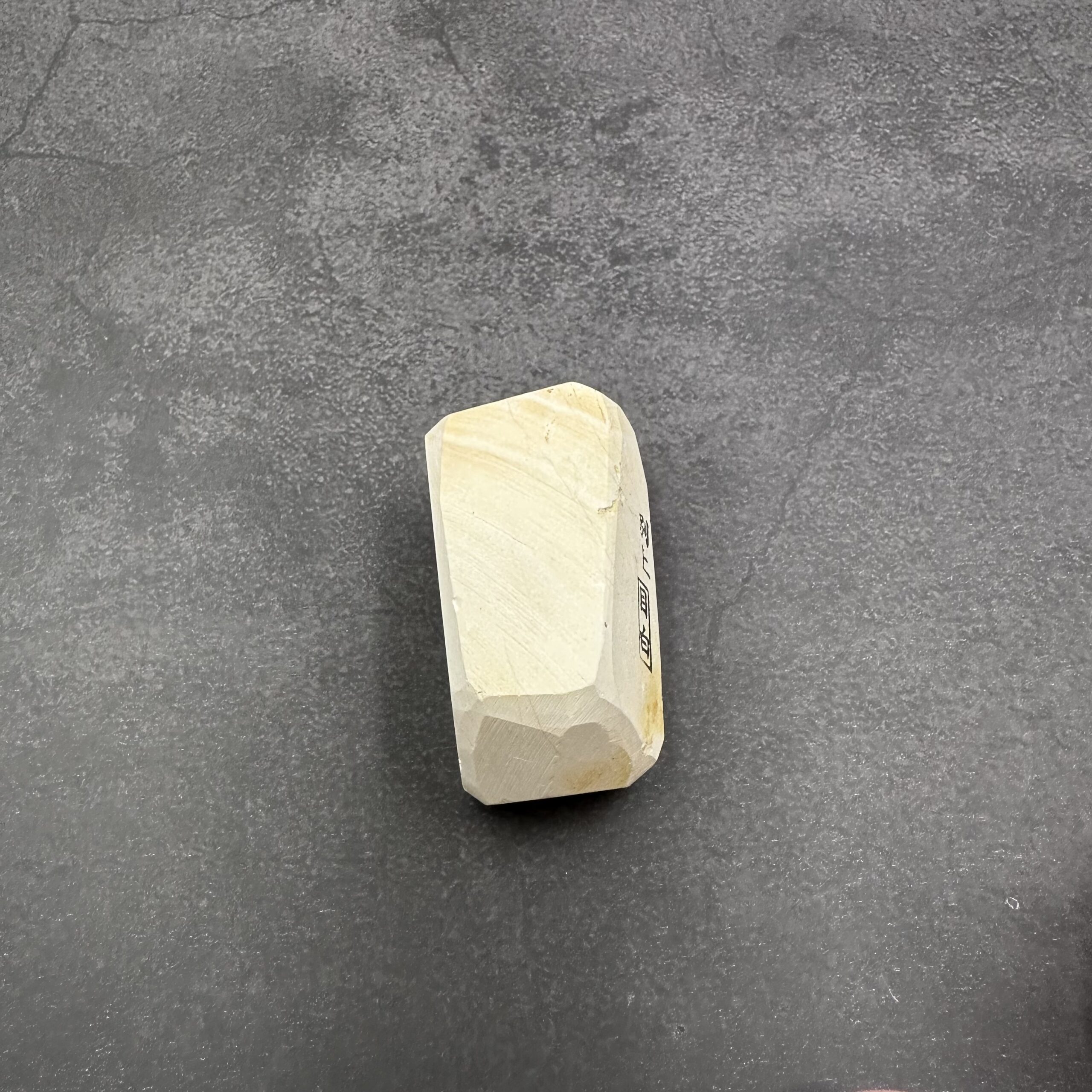

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 65g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Mejiro 50g

CHF29Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Asano Stamped Mikawa Shiro Nagura “Betsu Jou Grade” Mejiro 91g

CHF39Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Knife Anti-Rust and Disinfection Paulownia Wooden Box L size

CHF89Size Specifications

Large Size (Max 360mm blade)

- Internal Dimensions: 520mm x 70mm x 40mm

- Weight: 900g

- External Dimensions: 540mm x 90mm x 50mm

-

Knife Anti-Rust and Disinfection Paulownia Wooden Box M size

CHF89Size Specifications

Medium Size (max 300mm blade )

- Internal Dimensions: 440mm x 70mm x 40mm

- Weight: 760g

- External Dimensions: 460mm x 90mm x 50mm

-

Masakage x Yoshimi Kato Yuki Shirogami #2 Gyuto 210mm

CHF219Knife Type: Gyuto

Steel Type: Shirogami #2

Blade Length: 210mm

Blade Finish: Kasumi,(霞) Nashiji,(梨子地)

Blade Type: Double Edge– Handle –

Material: magnolia wood

Ferrule: red pakka wood -

Masakage x Koishi Aogami Super Bunka 170mm

CHF229Knife Type: Bunka

Steel Type: Aogami Super

Blade Length: 170mm

Blade Finish: Kurouchi,(黒打ち) Tsuchime,(槌目)

Blade Type: Double Edge -

Tsunehisa VG10 Sujihiki 270mm Forged Damascus

CHF199Knife Type : Sujihiki

Steel Type : VG10

Blade Length : 270mm

Blade Finishes :Forged Damascus -

Tsunehisa SLD Nakiri 155mm Damscus new version

CHF179Knife Type : Nakiri

Steel Type : SLD

Blade Length : 155mm

Blade Finishes : Damascus