=Japanese Whetstones=

Showing 1–12 of 15 results

-

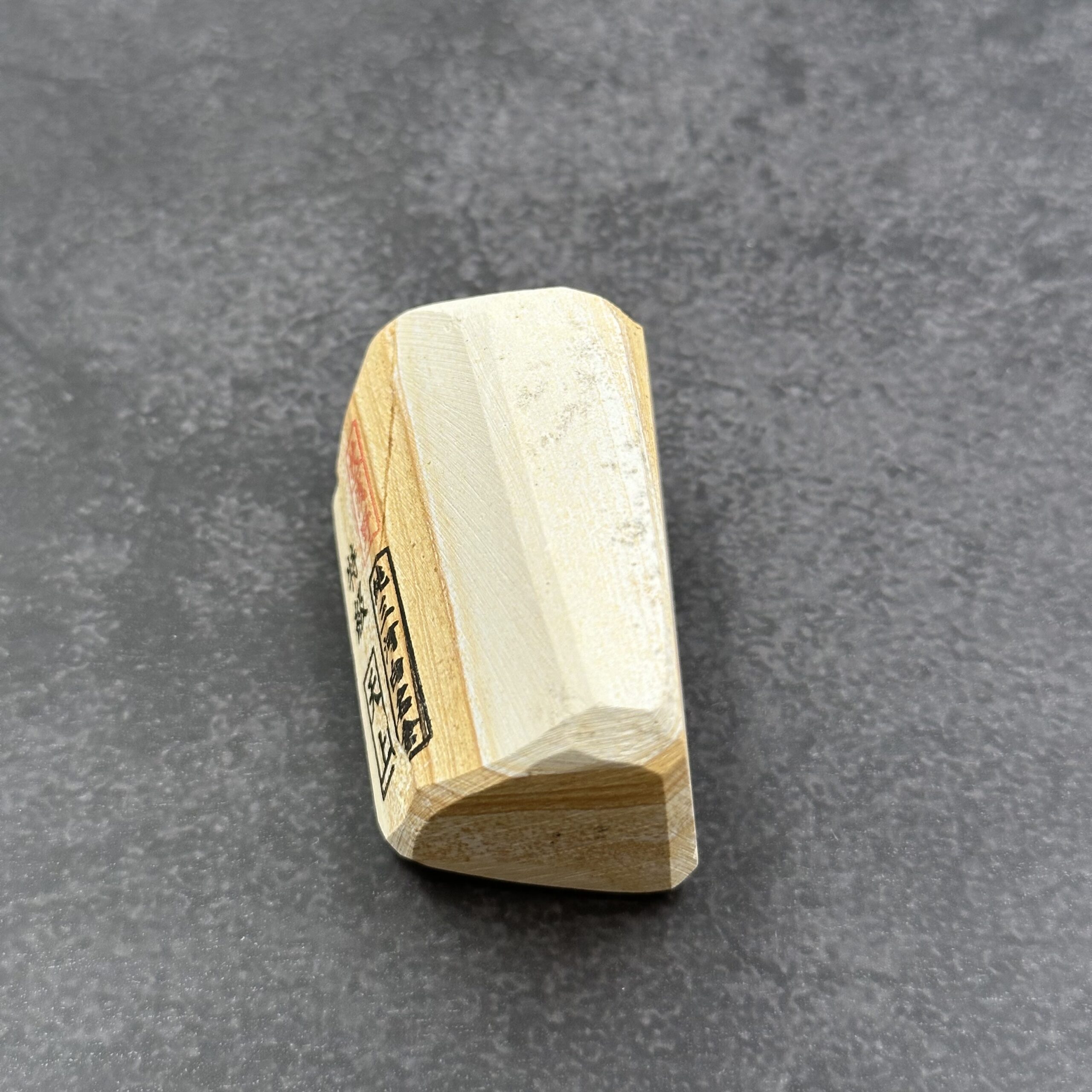

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 66g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

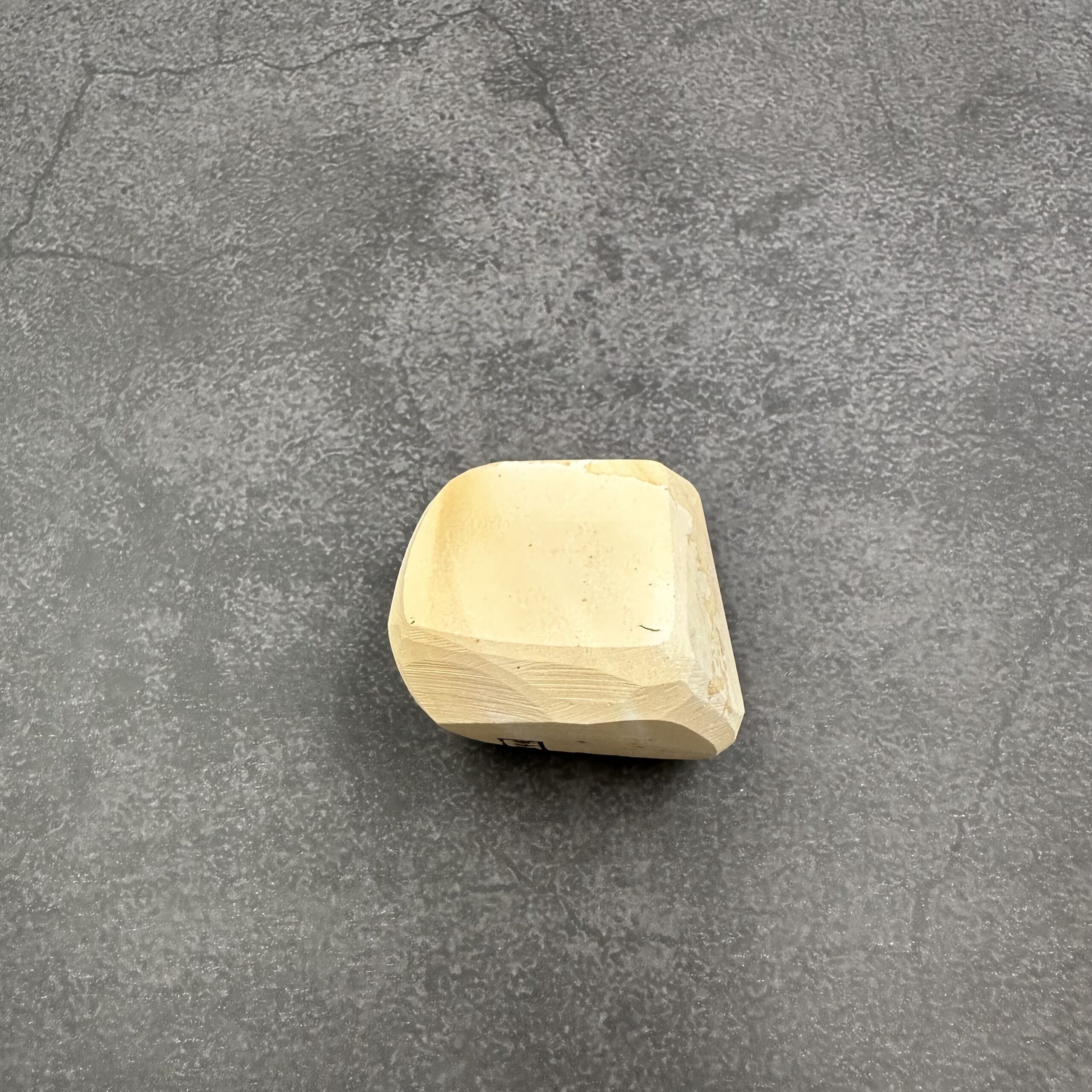

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 58g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

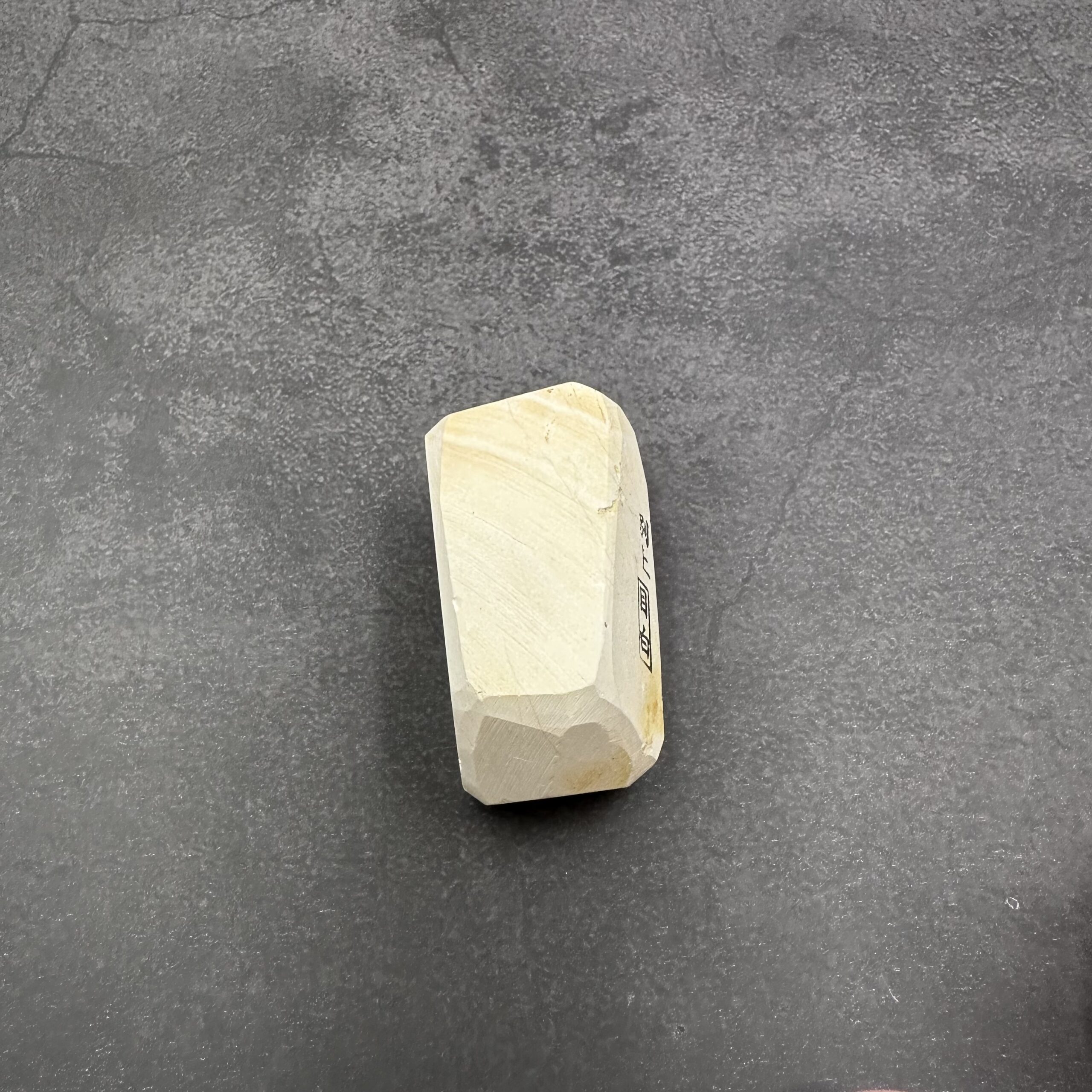

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Tenjyou 65g

CHF32Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Asano Stamped Mikawa Shiro Nagura “Tokkyu Grade” Mejiro 50g

CHF29Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Asano Stamped Mikawa Shiro Nagura “Betsu Jou Grade” Mejiro 91g

CHF39Using Nagura Stones for Whetstone Sharpening

One common technique for using a nagura stone involves selecting a nagura that is softer than the whetstone. When the nagura is rubbed on a wet whetstone, it creates a slurry composed of particles from the nagura mixing with the water on the whetstone’s surface. This method is particularly effective when using a hard whetstone, as it provides a stable working surface that resists dishing out during sharpening. The soft particles from the nagura enhance the sharpening process, and using a series of progressively finer naguras can yield a sharper edge than the whetstone alone, especially for tools like razors. Although this technique also removes some particles from the whetstone, the majority of the slurry comes from the nagura.

Another approach is to use a harder nagura on a softer whetstone. In this case, the slurry primarily consists of particles from the whetstone itself. This method is often employed on very hard whetstones that do not self-slurry—meaning they do not produce a slurry through the friction of the blade alone. However, it can also be used on softer whetstones that do self-slurry to expedite the process. Even with this method, a few particles from the harder nagura will mix into the slurry.

-

Knife Anti-Rust and Disinfection Paulownia Wooden Box L size

CHF89Size Specifications

Large Size (Max 360mm blade)

- Internal Dimensions: 520mm x 70mm x 40mm

- Weight: 900g

- External Dimensions: 540mm x 90mm x 50mm

-

Knife Anti-Rust and Disinfection Paulownia Wooden Box M size

CHF89Size Specifications

Medium Size (max 300mm blade )

- Internal Dimensions: 440mm x 70mm x 40mm

- Weight: 760g

- External Dimensions: 460mm x 90mm x 50mm

-

Naniwa Natural Leather Strop

CHF29CHF25Smooth Leather Surface

210mm x 70mm x 24mm)

Cushion Layer Under Leather

Non-Skid Pad on Bottom

-

JNAT Aiiwatani Tomae Saijo Lv4.5 Super Final Finishing

CHF259No. A01

Super Final Finishing

Hardness : Lv 4.5

Granularity : Lv 5

Size : 135x80x25mm

Weight : 749g -

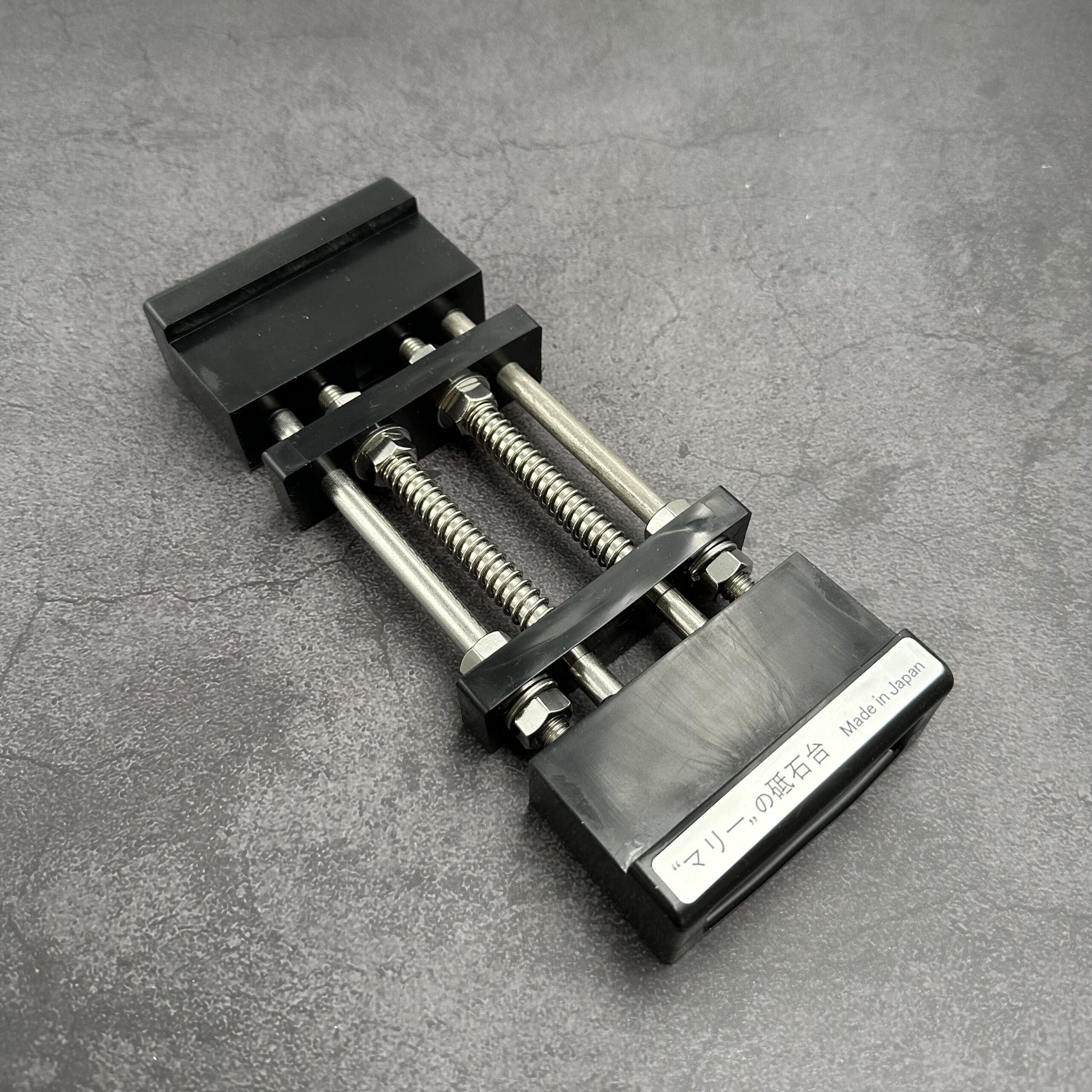

Whetstone Holder Plastic resin-Stainless Rod

CHF39CHF29Plastic resin

Stainless RodDoes not include whetstone

-

JNAT Aiiwatani Tomae Saijo Lv4.5 Super Final Finishing

CHF259No. A09

Super Final Finishing

Hardness : Lv 4.5

Granularity : Lv 5

Size : 150x85x25mm

Weight : 795g -

JNAT Aiiwatani Tomae Nashiji Toku sen-hin Lv4 Super Final Finishing

CHF199No. A07

Super Final Finishing

Hardness : Lv 4

Granularity : Lv 5

Size : 135x85x35mm

Weight : 888g